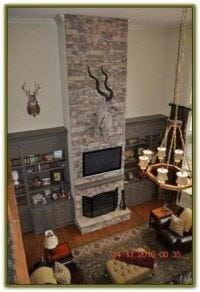

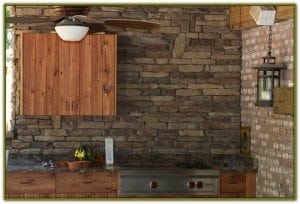

The skills required for any DIY stone veneer project will depend on the materials and methods used for the job. For instance, if you opt to use natural stone cut for use as a veneer, you will need good building skills even if you don’t cut the stone to size yourself. If, on the other hand, you decide to use man-made stone veneer, it will be a lot easier and quicker to install. And if you choose to use Native Custom Stone’s ingenious Go-Stone Panels, you don’t need any special skills at all.

Generally, natural stone veneer is a job for the professionals. Because of the weight, it will require a foundation, and the cut-stone veneer units will have to be laid in mortar. Depending on the size of the stone used, it might even need steel reinforcing.

Manufactured stone is a lot easier to work with, and it doesn’t usually need any concrete foundation or base. Go-Stone panels are even lighter

Skills Needed for a Faux Stone Veneer Project

Most faux stone veneer projects require basic building skills including knowledge of how to ensure everything is straight and square, as well as level and plumb. In essence, for any structure to be square it must have right-angled corners, horizontal surfaces must be flat and level and vertical surface must be plumb. All this means is that you need to know how to measure correctly and how to use a torpedo or spirit level since these tools allow you to check both horizontal and vertical surfaces. A builders’ square is useful for testing that corners are at right-angles.

While some faux stone veneer products can be laid dry and stacked without mortar, it is often better to use mortar. You can buy a pre-mixed product that comes in one bag for this.

It might take a bit of practice using a trowel to lay the mortar on the stone veneer, but it isn’t particularly different. If you work systematically, checking your vertical and horizontal levels as you go, there is no reason why you can’t achieve a professional finish.

Go-Stone is a unique product made partially from rubber tires. Because it comes in panels, it is a quicker process than laying a faux stone veneer. Nevertheless, you will need the same basic skills that relate to ensuring the veneer is straight, level, and plumb. Instead of working with mortar, Go-Stone panels are laid using a ceramic tile and stone adhesive.

Whether you opt for a faux stone veneer or Go-Stone panels, Native Custom Stone has products that offer lots of choices of finish and color. You’ll wonder why you ever considered using natural stone!

Follow Us!