Manufactured stone has become the go-to material for any homeowner that wants to add a little extra pop to their home. It looks exactly like natural stone but it is lighter, easier to work with, way less expensive, and tends to last a long time without deteriorating.

Nothing lasts forever though. Even manufactured stone will pick up the occasional crack or chip through normal wear and tear. It can’t be avoided but it can be easily fixed, unlike a natural stone veneer.

If you want to fix the cracks that are starting to show in your manufactured stone veneer you will need to gather a few supplies:

- Mortar mix

- Grout bag

- Hammer

- Wire brush

- Cold chisel

- Trowel

- Broom

Once you have everything you need, just follow these easy steps:

- Locate the first stone that you want to replace. You will use the cold chisel to carefully chip away the grout so that the stone comes loose. The best way is to hold the chisel at a 45 degree angle, pointing inward toward the stone you are removing. Once you have removed the grout, lightly tap the hammer around the edge of the stone to loosen it. If it still won’t budge, you may need to start chipping away at the stone itself.

- Once the stone is removed you should see the wire mesh it was attached to. Carefully use the wire brush to remove as much debris as you can without pulling the mesh away from the wall.

- When the hole is clear, measure it. If you have another stone of the correct size then you are ready to move on. If you don’t, you may need to rent a wet saw to cut one to size.

- Mix the mortar in a bucket until it becomes a paste.

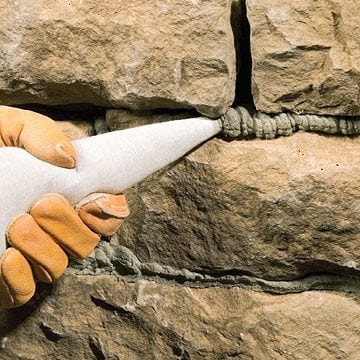

- Put a thin coating of the mortar directly onto the wire mesh then apply a thicker coat, about a half inch, onto the back of the stone. Press the stone firmly into place and use the grout bag to fill in around the edges.

- Move on to the next piece.

Manufactured stone is extremely resistant to damage from the elements but the part of your home they are attached to is not. If they are not properly installed by a professional, they can end up absorbing water and trapping it against your home. What makes this issue even more dangerous is you can’t see it happening. The manufactured stone wall will continue to look perfect while your wooden framing or drywall quietly rots away behind it.

Manufactured stone is extremely resistant to damage from the elements but the part of your home they are attached to is not. If they are not properly installed by a professional, they can end up absorbing water and trapping it against your home. What makes this issue even more dangerous is you can’t see it happening. The manufactured stone wall will continue to look perfect while your wooden framing or drywall quietly rots away behind it.

Follow Us!