By definition, faux stone is fake or false, or more kindly, it isn’t

So, perhaps the question should be: How can I prevent faux stone from looking fake? But first, it pays to get your head around the concept of faux stone.

What is Faux Stone?

There are different types of faux stone, the most common being cast in molds using a fine-aggregate concrete. Molds are made from different types of naturally occurring rock and stone so that both surface finish and size mimic what is found in nature. The concrete used depends on the preference of manufacturers, but it is commonly made with a mixture of cement, suitable building sand, and very finely crushed stone rather than the coarse aggregate used for the concrete used for foundations and footings.

Traditionally, faux stone was only available in single units in imitation of the individual units a stone mason would prepare for building. Faux stone veneer is considerably thinner than full-scale rocks or stones.

Native Custom Stone produces several manufactured stone veneer products, including a range of Custom-Fit faux stone panels that interlock, simplifying the installation process for DIY enthusiasts.

Native Custom Stone also produces an eco-friendly variant of faux stone veneer made with recycled materials including rubber tires. Lightweight and easy to install, they are sold in a panelized form.

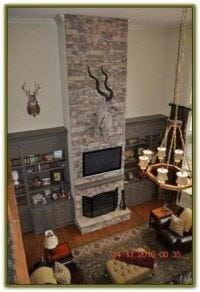

How to Prevent Faux Stone Looking Fake

When a stone mason builds a wall, he will choose his bonding pattern based on the stone used and the look required. Also, he will decide whether to lay the stone dry or to use mortar to bond it as bricklayers do when they build brick walls. Since no one individual rock or stone will look identical to another, there is no risk that the stone elements will look fake. But, the skill of a stonemason is to make the wall itself look natural!

If you’re going to build a faux stone wall or have one built, here are a few tips to help ensure it won’t look fake.

- Choose a

product that looks natural.

- If using individual stones make sure you buy a good selection of different stones to be able to create a more random impression.

- Faux stone panels are manufactured so that adjacent stones are not the same, making them a good option for DIY.

- Choose a product that looks reasonably similar to natural stone found in your region and install it so that it looks like walls typically built with these materials.

- Take care not to install faux stones and panels that are the same right next to or above one another. A repetitive pattern is a dead giveaway, and if a faux stone wall looks fake so will the faux stones it is built with.

- Make sure that the design of the installation is something that could genuinely be built with natural stone. For instance, if it’s used above a wide opening and covers the lintel, it’s likely to look very fake.

Whether you want to use faux stone for a DIY project or have a contractor do the work for you, contact Native Custom Stone for more information. Alternatively, Go-Stone and Custom-Fit faux stone panels, and other simulated stone products are available from Home Depot online or from Build Direct.

Follow Us!