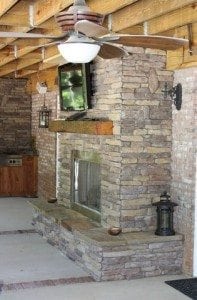

We want to make sure that you keep your custom stone looking great for years. Part of this is making sure that it’s well maintained and clean. As you know, manufactured stone veneer is different than a natural stone, and needs to be cared for differently. A good cleaning every two-three months should keep your manufactured stone looking new.

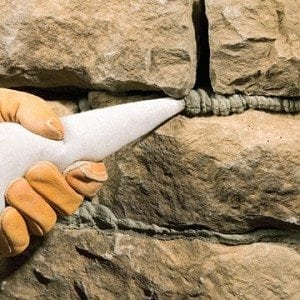

Keep in mind when installing your stone not to leave mortar on any surface. Mortar should be brushed away as the stone or brick is installed. If the surface is properly protected during the application, cleanup will be much easier. After the mortar sets for 24 hours, wash the job with a water hose to eliminate excess dust. Once the Stone or brick veneer has dried, apply a sealer for maximum protection.

5 Steps to Properly Cleaning Manufactured Stone Veneer:

- Thoroughly mix approximately one cup of Laundry detergent into 3 gallons of hot water. Never use detergents with bleach, any type of acid, or a pressure washer.

- Rinse the stone/brick with water to remove loose debris.

- Using a circular motion scrub the dirtiest areas first using a medium bristle brush.

- Rinse the cleaned area thoroughly, removing all detergent and suds.

- Let dry, if you still see dirt and debris, repeat the cleaning process. Once completely dry and clean, seal.

Remember you don’t need to clean your manufactured stone often, if there is a little mud or muck just rinse with a hose or water. Or, if you have accent stone veneer inside your home, just wipe it down with a damp cloth.

They do make special detergents for manufactured stone if you wanted to keep it on the safe side, but a mild dish detergent or even laundry detergent will do. If you don’t have manufactured stone in your home yet, but have been thinking about it, Native Custom Stone has a wonderful selection of manufactured stone veneers to choose from. They also have distributors all over Georgia, and you can buy online from Build Direct or Home Depot!

Follow Us!