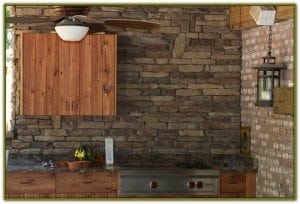

Have you heard of Go-Stone yet? If you are planning any DIY projects with stone elements in them then you owe it to yourself to read more at www.HomeDepot.com. It is an Eco friendly stone panel system that was created specifically for the “Do it Yourself” crowd.

Go-Stone requires very few tools to install and it is created almost entirely from recycled materials. It is not recommended for outdoor use but Go-Stone is perfect for projects like:

- Kitchen back splashes

- Fireplaces

- Accent walls

- Bathrooms

Go-Stone is:

Light weight – Compared to standard building materials of its type, Go-Stone is incredibly light. This makes it very safe to work with and a lot easier for a single person to install.

Light weight – Compared to standard building materials of its type, Go-Stone is incredibly light. This makes it very safe to work with and a lot easier for a single person to install.- Easy to install – Some building materials like natural stone require a hefty investment just to get the tools you will need for installation. Go-Stone doesn’t require any mortar to keep it in place or grout to fill in the cracks. A quick trip to your local hardware store will get you the few simple tools you need to create a finished professional look.

- Environment friendly – The material is made from a special blend of crumbled rubber that started life as a tire. For every five squares of Go-Stone that you purchase you will be removing one old tire from an overburdened landfill. Considering that 242 million tires are thrown away per year in the United States and fewer the 7% are recycled, it is a great way to make a difference in your environment. Plus, you get a really professionally looking new design element for your home.

This innovative stone panel system will be available in three colors and it will have compliments like electrical surrounds and water table. With a product like this, even people with no experience in home repair will have the ability to improve the look of their home with stone. Go-Stone is available online at HomeDepot.com nationwide, contact Native Custom Stone today to find out more about this revolutionary new product.

Follow Us!