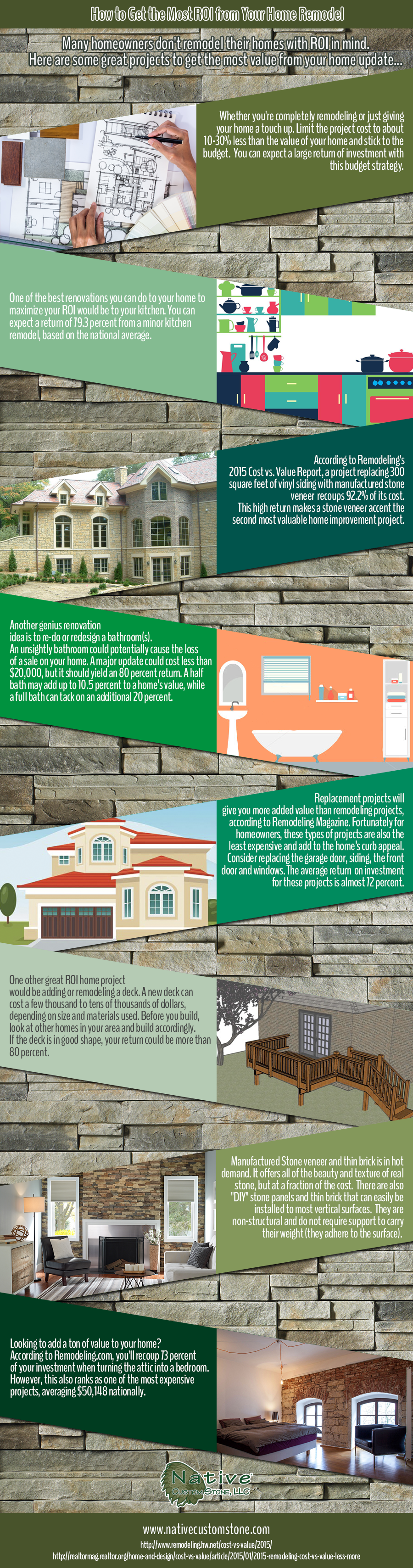

DIY home improvement projects can be challenging, rewarding, and if you can do relatively simple makeovers easily and quickly, they can be a lot of fun too.

The use of faux stone as cladding inside the house is one of the most effective makeover ideas. You can use it on feature walls in living areas; between counters and cupboards to transform kitchens; as a backdrop for fireplaces, bars and other special areas; and to add character to stairwells, lobbies and entrance halls, however big or small they may be.

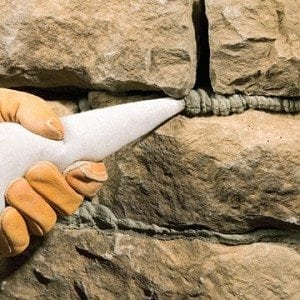

But until relatively recently, working with faux stone has required basic masonry skills because it was molded from concrete and laid using mortar. Doing it this way is incredibly effective, but does take time, and can be messy.

DIY stone panels (Go-Stone) are just as effective, but quite different. A truly DIY product launched by Native Custom Stone in 2013, Go-Stone panels are made with recycled tires, making them lightweight and environmentally friendly. They are also incredibly easy to install with no formal skills, and it’ll take you about a fraction of the time it would to install traditional faux stone panels.

DIY stone panels (Go-Stone) can be used in a multitude of different ways, to create lots of different effects, but the installation process remains the same – and the bonus is that anyone can do it!

The Installation Process for DIY Stone Panels (Go-Stone)

The first step is to measure the surfaces you are planning to transform using DIY stone panels (Go-Stone). The next is to order what you need from Native Custom Stone, select Home Depot stores, or from BuildDirect.com

The first step is to measure the surfaces you are planning to transform using DIY stone panels (Go-Stone). The next is to order what you need from Native Custom Stone, select Home Depot stores, or from BuildDirect.com

There will be three different sized panels in each pack; these measure 16, 12 and 8 inches. They should be alternated according to the illustration on the packaging, for example, with a 12- or 8-inch panel above a 16-inch panel. Note that corner pieces are packaged separately. You will need these if you are working on pillars or any areas that don’t end at the corner of a wall.

The second step is to ensure that you have everything you need to do the installation work.

There are so few tools and equipment needed, if you’re already into DIY there’s an excellent chance you will have it all already. You’ll need:

- Measuring tape to measure the surfaces as well as to check where the panels will go.

- Drywall or wet-cut saw to cut some of the panels to ensure end pieces fit perfectly.

- Torpedo or spirit level to make sure the panels are level and plumb.

- Notched floor trowel.

- Ceramic tile and stone adhesive, preferably ready mixed.

Now you’re ready to get started.

- Make sure the surface to be clad is clean and dry.

- Cover the floor in and around the work area with canvas tarpaulin or plastic sheeting.

- If you have corner pieces, it’s important to start working from a corner.

- Apply adhesive to the first panel using the trowel. Make sure it covers the whole surface.

- Push the first panel firmly into place and use the level to make sure it really is level. Never rely on existing surfaces for this – not even the existing floor.

- Lay all the panels along the baseline.

- You may have to cut the last panel to fit. If you have corners at both ends, you will have a cut panel in the middle, in which case it’s best to cut two of the panels and butt them together for a neat fit.

- When you lay the second row of panels, make sure you don’t lay identical ones on top of one another. If you do this you are likely to create a visual seam.

- Continue to check your levels as you work.

- And that’s all there is to it. Simply keep laying your new simulated stone cladding until you’re done.

Contact Native Custom Stone for more information about the different stone types and colors for your next project using DIY stone panels (Go-Stone).

Follow Us!